It’s not just about manufacturing.

Custom workholding solutions are all about understanding the manufacturing requirements. It starts with a good basic understanding, as well as the crucial location and holding requirements and standard areas to package the workholding accurately. Brown & Holmes has the expertise to refine the design and give cut-outs and access to certain areas. There is a constant flow of development between the design and manufacture.

Experts at custom workholding productivity solutions perfect for each customer

Brown & Holmes brings the whole package together: trade operation, cycle time, rigidity, and access to machining. And their commitment doesn’t stop at delivery. They provide ongoing tooling, installation support and technical backup to all customers. They have the experience to understand the customer’s requirements and provide the right solution, all under one roof.

All this enables Brown & Holmes to deliver manufacturing productivity from our concept process to installation on your shop floor.

For more information or to speak to a consultant, call 01827 63591 or email info@brownandholmes.co.uk

Productivity enhancing workholding solutions, all under one roof.

Brown & Holmes are experts in workholding solutions that allow customers to improve their manufacturing productivity. Their considerable knowledge and world-class expertise, built on years of experience and a highly skilled workforce, are evidenced by an impressive track record of providing solutions to blue-chip customers for over 80 years.

Expert design and engineering teams execute everything in-house, working closely with customers from initial concepts and design to manufacturing high-quality parts and solutions to shorten the time it takes to get customer’s products to market. When additional components are required, top-quality products such as hydraulics from Roemheld are used.

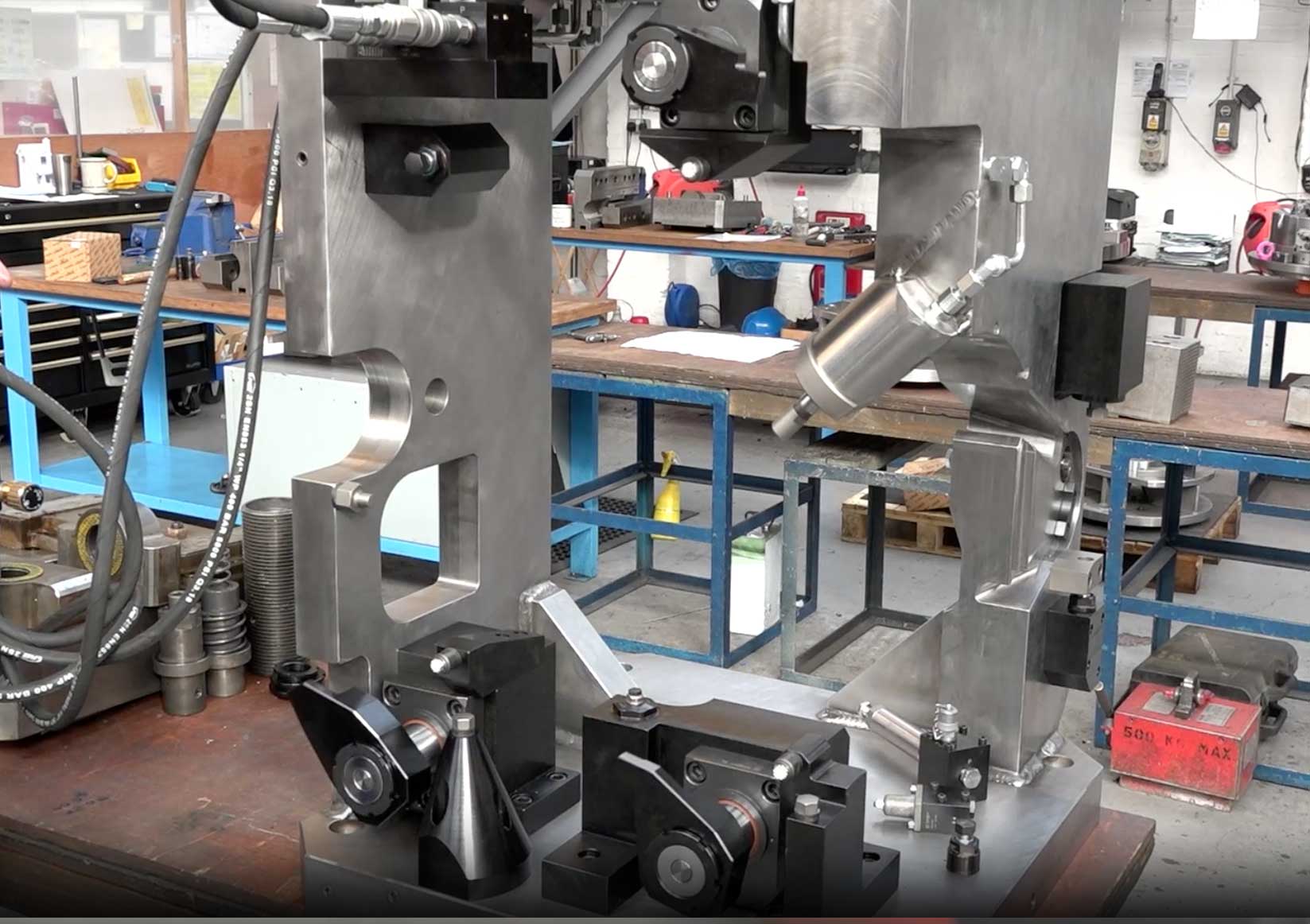

Prismatic workholding. A showcase for capability

If there were a product that best explained all of Brown & Holmes’s workholding capabilities in one, it would be prismatic workholding. Even from the design stage, Brown & Holmes’s skill and ability to understand customers’ requirements allow them to adapt the design and put the best solution forward if, as sometimes happens, the parameters change.

A Brown & Holmes engineer explains, “From the order going into the design office, we have a strong team that uses multiple systems to suit the customer’s requirements, and manufacture is 100% in-house. For hydraulic components, we use a supplier, Roemheld, and then the fixture is fully assembled, tested and inspected here at Brown & Holmes.”

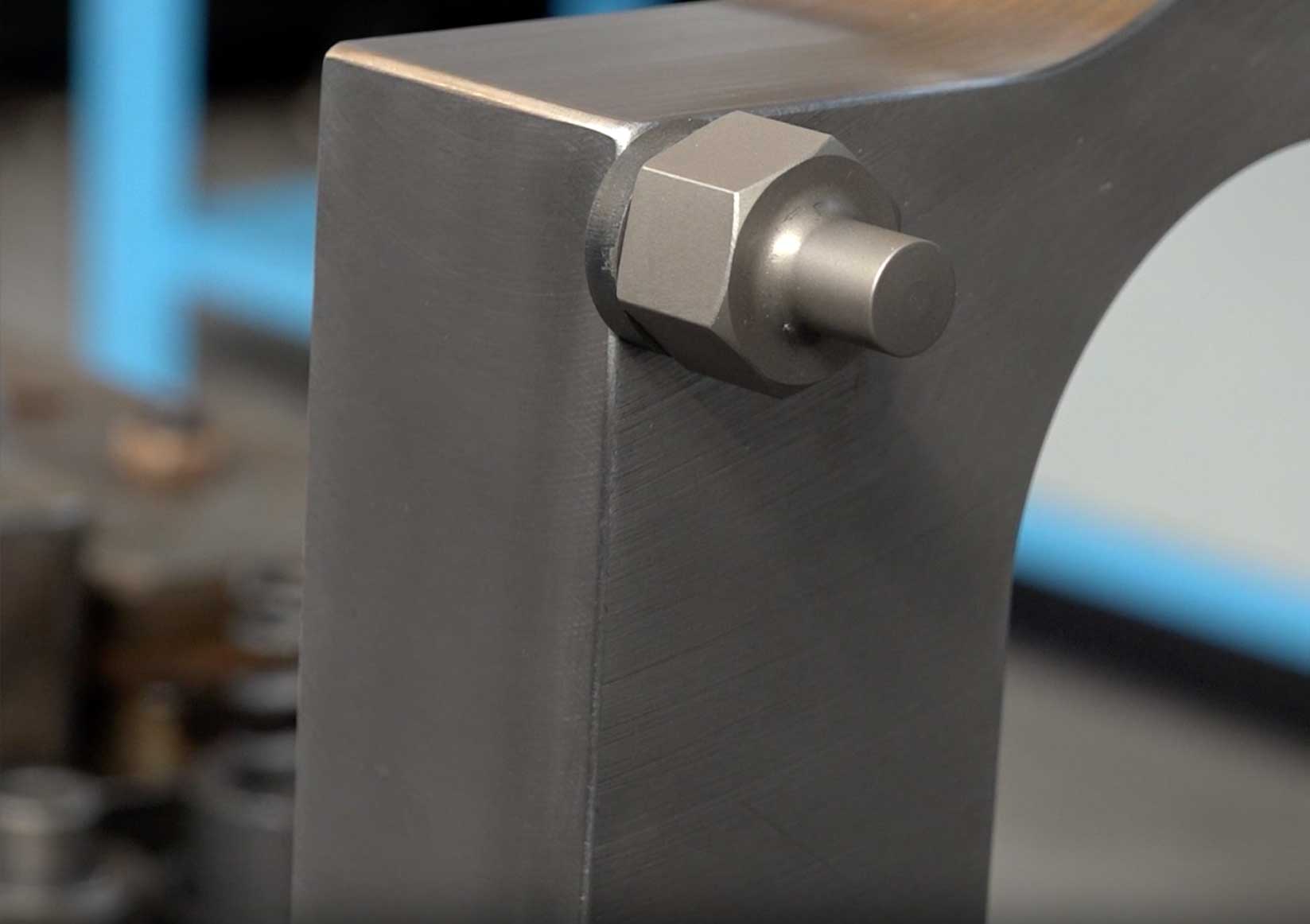

“The solution is all-encompassed on the fixture. There is the hydraulic coupling, which engages and disengages the locking mechanism, the pipework on top of the system is sequenced and controlled so that the correct pistons, clamping and work supports are applied in the correct order. This ensures the component is loaded, pushed into position, supported and clamped accurately.”

The prismatic workholding components at work

As with most prismatic work holding solutions, Brown & Holmes utilises a 321-location strategy, with three back-stops, two bottom stops, and a side stop. As it is hydraulically sequenced and actuated, there is a pusher to locate the component and ensure it is pressed firmly against the work fixture, as well as work supports or touching locks, which are hydraulically actuated and locked into position. Swing clamps then come in to hold the component down and back into the located position.