Capabilities

Manufacturing capability and facility

B&H is ready for the future. Additional workshop space and capacity, as well as specialised equipment and assets enable us to provide extensive and automated production of quality components that are critical elements in many processes.

B&H has the capacity to work in all alloy steels, all special steels, mild steels, titanium, aluminium, exotic materials such as hafnium, and different resins.

Our manufacturing site at Apollo Park contains a wide range of traditional machinery for precision machining services and machine work holding, automation, mechanical handling solutions. Assets include 5-axis machines, CNC machines, horizontals, verticals, wire erosion machines and lathes.

Brown & Holmes’ second facility on the Anders site brings our total footprint to 36 000 ft2 incorporating a robot demonstration area, a dedicated assembly, test and inspection facility plus equipment to provide specialist 10-tonne lifting capabilities. It also houses the Apprenticeship Training Centre and 3D printers for prototyping, with the 3D printing machines, a Fortus 450 mc and a F170 3D, being the latest 3D printer technology from Stratasys. These are used for additive manufacturing which produces parts and prototypes across a wide range of materials, including carbon fibre, polymers, acrylics, thermoplastics and polyurethane.

Our third site in Derby is dedicated to the design, manufacture and assembly of electrical operating cabinets, consoles and many other control devices.

Outsourced processes include welding and fabrication; B&H has 2–3 subcontractors (pre-approved by B&H and customers) for each process.

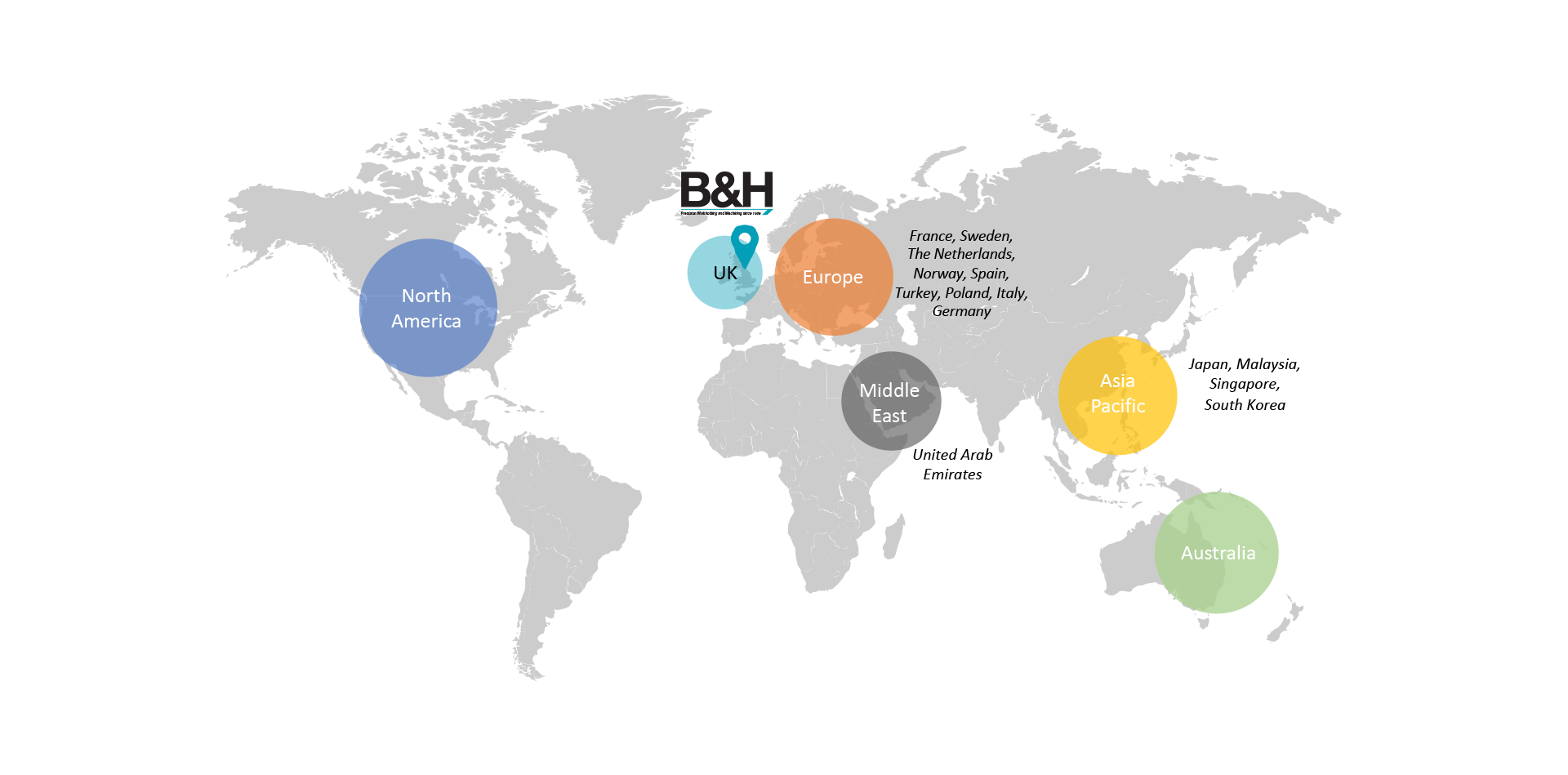

Global reach

Brown & Holmes have built a reputation across the globe for exceptional quality workmanship and their products and services are in demand by organisations in North America, Europe, the Middle East, Australia and the Asia Pacific area.

Brown & Holmes work on site with your team, in your location to ensure maximum production uptime. We assist with installation and training, provide full technical back-up, and support planned maintenance programmes.

Staff capability

Brown & Holmes is strongly led from the top down by joint managing directors Kevin Ward and Carl Baker. Brown & Holmes wouldn’t be where they are today without the deep industry expertise and the experience in precision manufacturing of staff with some 40+ years in the business.

These skills are scarce in the UK, and in order to ensure a continual supply of qualified staff the company runs a successful apprentice training programme.

Key positions in the business include engineering and the design team, quality control and HSE, and defence and operations management as part of a 60+ strong team.

Who we work with

Who we work with

Accreditations

Making it easier for global leaders to work with us.